Jounce Bumpers: Everything You Need to Know

1/14/2014

Your tuck’s got ’em. Our air springs have ’em. They’re important in protecting your truck.

The jounce bumper.

Commonly known as a “bump stop,” the jounce bumper was initially used to prevent the abrupt and harsh bottoming-out of the suspension when under full compression.

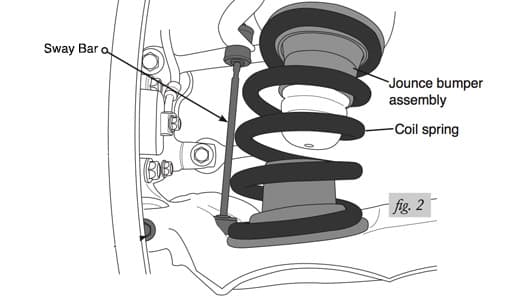

Over the years this original design has changed and the jounce bumper has been integrated into the vehicle’s suspension design.

Commonly manufactured from closed-cell foam, the jounce bumper absorbs impact and dampens noise, vibration, and harshness by preventing the suspension components from fully compacting during shock impacts caused by heavy loads, potholes, curbs, or objects in the road.

The modern jounce bumper also acts as a progressive compression spring under loads that are approaching full compression, offering a smoother ride and improved handling over a wide range of driving and load conditions.

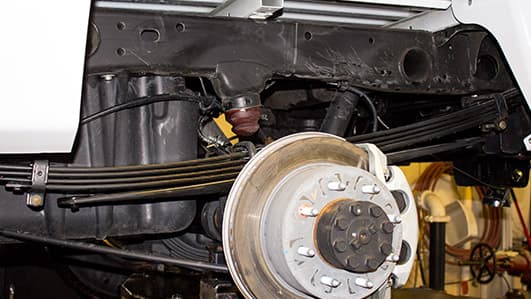

On vehicles equipped with leaf spring suspensions, the bump stop is typically mounted between the axle tube and the chassis side rail.

On vehicles equipped with coil spring suspensions, the jounce bumper is typically mounted on the bottom of the frame at the top of the coil spring.

Since air spring installation often requires the removal of these jounce bumpers, Air Lift’s heavier-duty applications – the LoadLifter 5000 Ultimate and LoadLifter 7500 XL Ultimate – include jounce bumpers inside each air spring, providing the ultimate solution for towing and hauling heavy loads.

Made from closed-cell urethane foam, the jounce bumper inside LoadLifter 5000 Ultimate and LoadLifter 7500 XL Ultimate kits provide a factory-like cushion that absorbs shocks and controls extreme suspension travel in heavily laden vehicles.

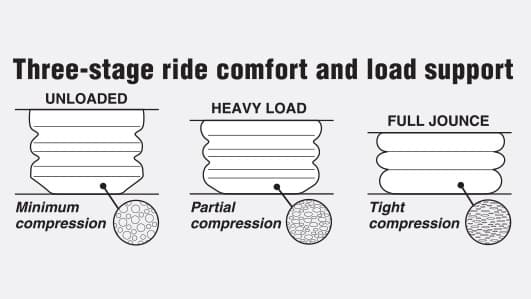

Not merely a bump-stop, these integrated jounce bumpers offer three-stage compression that loosely simulates variable-rate mechanical springs.

These air springs provide:

- Up to 5,000 lbs of load-leveling capacity*

- Easy adjustability for a safe, comfortable ride, loaded or unloaded

- Maintenance-free operation – the air springs can safely run with zero air pressure in an emergency situation (We recommend maintaining the minimum air pressure for the ultimate ride comfort.)

- Enhanced three-stage ride comfort, while acting as a damper allowing a smooth transition to full compression

- Elimination of harsh jarring on rough roads

*Never exceed manufacturer’s recommended GVWR.